Blogs

Grading automation saves money and improves customer satisfaction

In our previous blog, we discussed about factors impacting the growth of refurbished smartphone market, and the current practices utilized in the field. There are multiple factors like lower prices and more sustainable consumer habits that contribute towards the growth. There is room to improve the quality of the refurbishment and grading process, and one of the keys to success is automation.

In this blog, we will present how automation can improve quality of the refurbishing and grading processes and lead to reduced expenses and increased customer satisfaction. We will be using analysis results gathered with OptoFidelity SCORE, a fully automated test system for second-hand smartphone grading.

In this blog, we will discuss briefly about challenges related to manual grading, repeatability comparison of manual vs. automatic grading and benefits of improving reliability and repeatability of the grading process.

As discussed in our previous blog, there are many issues related to the manual grading. Inspecting hundreds of phones manually and on a daily basis is repetitive and tedious. This is not only a tiresome task but also an error-prone.

Frequent breaks to employees can slightly help with regaining focus, but it won’t solve the fundamental issue that is the repeatability of the process. The final grade is affected by individual's bias and current stress levels. Increase in number of manual operators at a refurbishing line further cumulates the affect.

Manual vs. automated grading

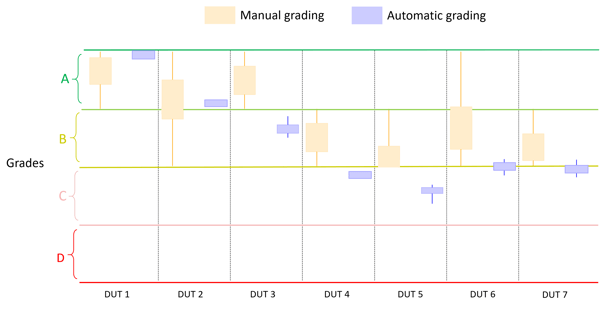

To compare the affects, we conducted an experiment that involved five human operators and two OptoFidelity SCORE testers. A bunch of random second-hand smartphones were selected as DUTs. The human operators were given instructions to grade the smartphones into 4 different grade categories. The description for these categories is given in the table below. The used grade categories and descriptions are based on the criteria used by companies operating in the field.

|

Grade |

Description |

|---|---|

| A - LIKE NEW |

Like new condition

|

| B - OKAY |

Small damages allowed

|

| C - FAIR |

Clearly visible wear and damages

|

| D - BAD/REPAIR | Severe damage / Cracks |

The same devices were also graded with two OptoFidelity SCORE testers. The grading logic used with OptoFidelity SCORE utilizes machine learning algorithms, where characteristics of different categories were taught by using example devices. The devices used in training were not the same that were used in the tests.

Figure 1. All devices used in the tests were graded 3 times with both testers, resulting in total of 6 grading results for each device. With this experiment, we were able to evaluate the intra- and inter-level variation in the automatic grading. Results for the test are visualized in this figure.

Figure 1 shows that the variation in manual grading is much greater as compared to the automatic grading. Humans tend to perceive the condition of the device differently leading to larger variation in grading.

Repeatability of the grading process is essential so that customers can trust they are receiving quality products. Grading errors and unnoticed defects can lead to complaints and reduce the customer trust. Building the trust again is hard. Investing into grading automation improves the quality and repeatability of the grading process, and companies can assure high customer satisfaction.

To discuss about automation products for refurbishment industry, contact Kari Järviö, Head of Refurbishment at OptoFidelity.

In our next blog, we will take a deeper look at the OptoFidelity SCORE tester, and what other benefits it offers to improve the refurbishment process.

Written by