Blogs

Illuminating AR: Why Littrow Diffractometers Excel in Evaluating Diffractive Gratings for Augmented Reality Devices

In the rapidly expanding field of augmented reality (AR), the precise measurement of diffractive gratings used in AR devices is crucial for optimizing their performance and user experience. Therefore, the choice of measurement technique can significantly impact the accuracy and efficiency of the process. While Scanning Electron Microscopes (SEMs) have been a popular choice, Littrow diffractometers are emerging as the superior alternative for evaluating AR diffractive gratings. In this blog post, we will delve into the reasons why Littrow diffractometers should be your go-to choice for assessing the performance of diffractive gratings in AR devices.

.png?width=6000&height=4000&name=MicrosoftTeams-image%20(12).png)

1. Preserving AR Grating Integrity

Littrow diffractometers hold a crucial advantage over SEMs due to their non-destructive analysis capabilities. SEMs necessitate coating the AR grating sample with a conductive material, which may alter the grating's properties or even cause damage to the delicate structures. Littrow diffractometers, on the other hand, employ a laser beam to assess the grating quality without physically contacting the sample, ensuring the AR grating's integrity is maintained.

2. Real-Time Optical Performance Assessments

For AR applications, obtaining real-time, in-situ measurements of the grating's optical performance is vital. Littrow diffractometers analyze the diffraction pattern produced by the AR grating, offering immediate and accurate information about diffraction efficiency, polarization properties, and other essential parameters. In contrast, SEMs provide only morphological data, necessitating separate measurements and simulations to correlate with optical performance, resulting in less precise and efficient evaluations.

3. Adaptable Wavelength Range for AR Applications

Littrow diffractometers enable easy wavelength adjustment of the incident light to match the AR grating's specific requirements. This adaptability allows for the accurate measurement of AR gratings designed for diverse applications, covering the ultraviolet (UV) to near-infrared (NIR) spectrum. SEMs are limited by their imaging capabilities and cannot directly supply information on the grating's performance across different wavelengths.

4. Consistency and Precision for AR Grating Measurements

High repeatability and reproducibility are hallmarks of Littrow diffractometers, ensuring precise and consistent measurements even when operated by different users or when evaluating multiple AR grating samples. Further, by their very nature, Littrow diffractometers measure gratings with a precision that is orders of magnitudes smaller than the period of the grating it measures. In contrast, SEMs are more susceptible to operator-induced variations, with image quality influenced by factors such as sample preparation, electron beam parameters, and microscope settings. Worse still, the resolution of an SEM tends to be insufficient to measure a diffractive grating as precisely as a Littrow diffractometer would.

5. Streamlined Analysis for AR Grating Evaluation

Littrow diffractometers offer simplified operation and minimal sample preparation, making them user-friendly even for those with limited optics experience. In addition, the results obtained are easily interpreted, streamlining the AR grating evaluation process. In contrast, SEMs demand extensive sample preparation, and image analysis can be time-consuming and require electron microscopy expertise.

Conclusion

When assessing the performance of diffractive gratings in augmented reality devices, Littrow diffractometers provide numerous advantages over SEMs. Their non-destructive analysis, real-time optical performance measurements, versatile wavelength range, high repeatability and reproducibility, and streamlined analysis make them the optimal choice for AR researchers and manufacturers. By selecting Littrow diffractometers, you can obtain precise and reliable data to refine your AR gratings and propel your AR devices to new heights of performance and user experience.

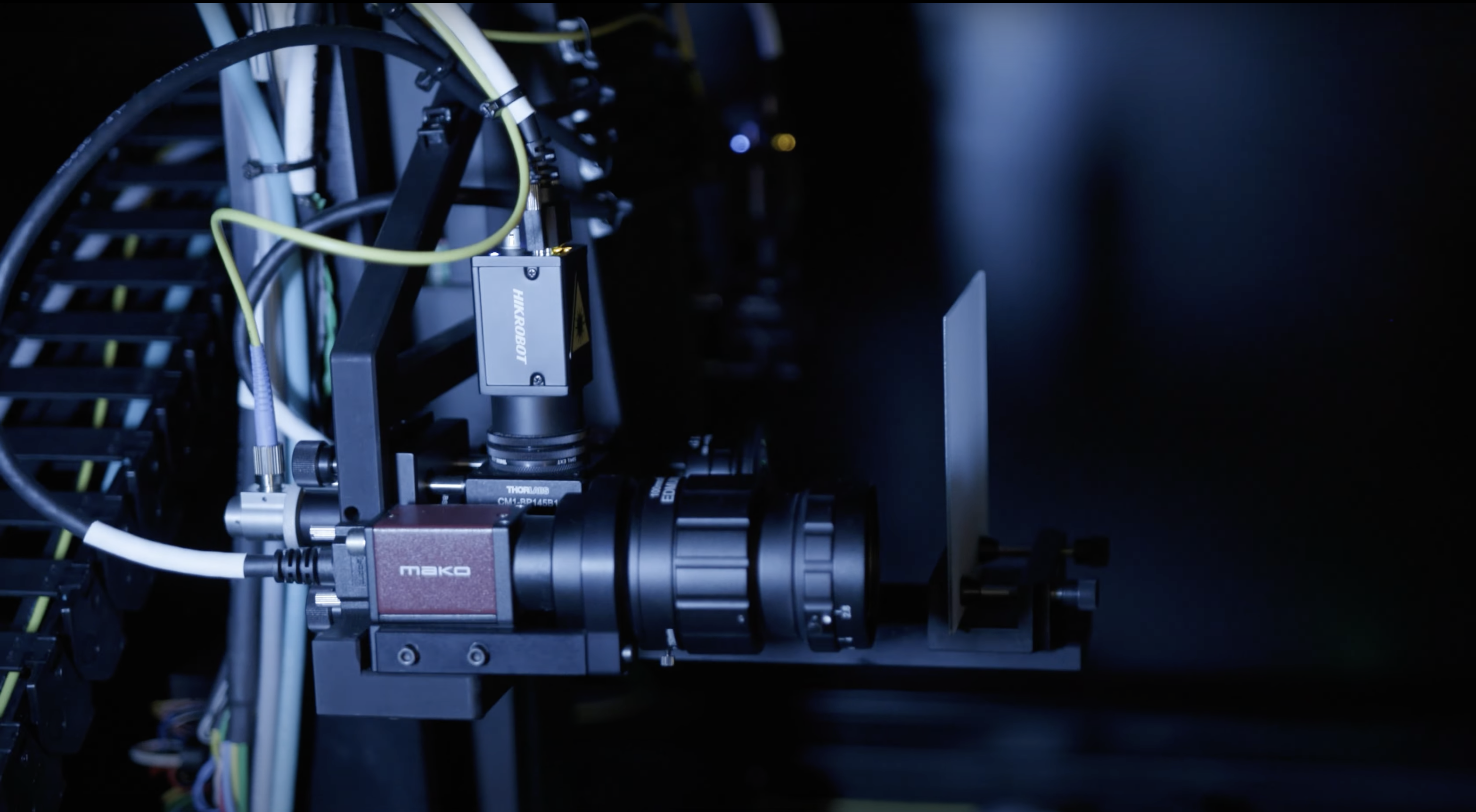

Contact us to learn more about how this technology is implemented in our newest test system OptoFidelity WG-GAT.

Written by