Blogs

Using Industrial Automation Testing to Increase Performance Excellence and Output of HMDs

With the ramp-up of head-mounted display (HMD) production, there’s an opportunity to gain a competitive advantage through manufacturing efficiencies. Waiting to solve these problems in the production stage no longer serves you. We suggest moving testing into the earliest stages of product design. Integrating performance test engineering into your mass production process can help discover bottlenecks and challenges before and during production.

What are the implications of implementing earlier testing, like labor requirements, equipment, and the additional time to market? Automated optical metrology testing systems can help to alleviate these barriers and solve performance issues before they even appear. We have identified a few steps that you can take to make sure you can improve productivity and establish world-leading quality and performance in your optical technology.

Steps to improve and maximize your HMD production process:

- Gain end-to-end system performance visibility with the shift-left approach

- Get performance improvement recommendations based on comprehensive statistical analysis

- Apply technology-agnostic testing strategies suitable for any device, form factor, or use case

Gain end-to-end system performance visibility with our shift-left approach

A shift-left approach means that testing is incorporated into the early design and development stages. For HMDs and other AR/VR wearable technology, this approach includes testing individual components separately before using them as a system. “Fail early” can reduce cost and waste, when well-designed testing systems start at the materials and components level for early detection of defects.

Many HMD tech companies detect defects at the wafer level, reduce waste and optimize limited supply.

The shift left approach enables project teams to test and correct earlier. Optical measurements, such as field of view, eye-box location and size, MTF, eye-side image quality, luminance uniformity, and others are critical to ensuring product performance excellence. Early testing combined with precision robotics can maximize quality and efforts.

Get performance improvement recommendations based on comprehensive statistical analysis

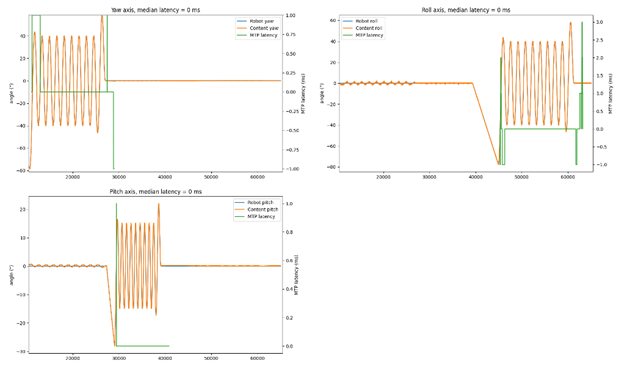

Testing earlier helps to build the dataset to produce and launch your HMD display technology. We’ve seen success in testing when operators identify and run realistic performance testing scenarios on your product during the development cycle and compare results after any design or software changes. At OptoFidelity, we offer expertise and in-depth reporting of performance test results in an easily readable format, as well as the raw measurement data from performance tests for internal analysis. An example is pictured below.

Image 1. Motion-To-Photon (MTP) latency measurement results

Image 1. Motion-To-Photon (MTP) latency measurement results

Apply technology-agnostic testing strategies suitable for any device, form factor, or use case

Accurate and repeatable measurements allow you to meet your requirements across the product portfolio or component selection. Precision robotics can complete measurements faster and more accurately than humans. Compatibility and interoperability can be barriers to adopting automated testing systems for HMDs. Our test platforms can accommodate a variety of physical form factors, data interfaces, and operating systems or provide component-level testing.

These three steps can significantly impact the overall production efficiency and image quality of your HMDs. Start building your competitive advantage with the right testing solution.

Are you interested in learning more about what you can do to improve your operations to increase HMD image quality?

Discover what automated testing systems can do.

Written by