Blogs

Machine vision-based cosmetic defect detection enhanced with AI - Make or break your used smartphones business case

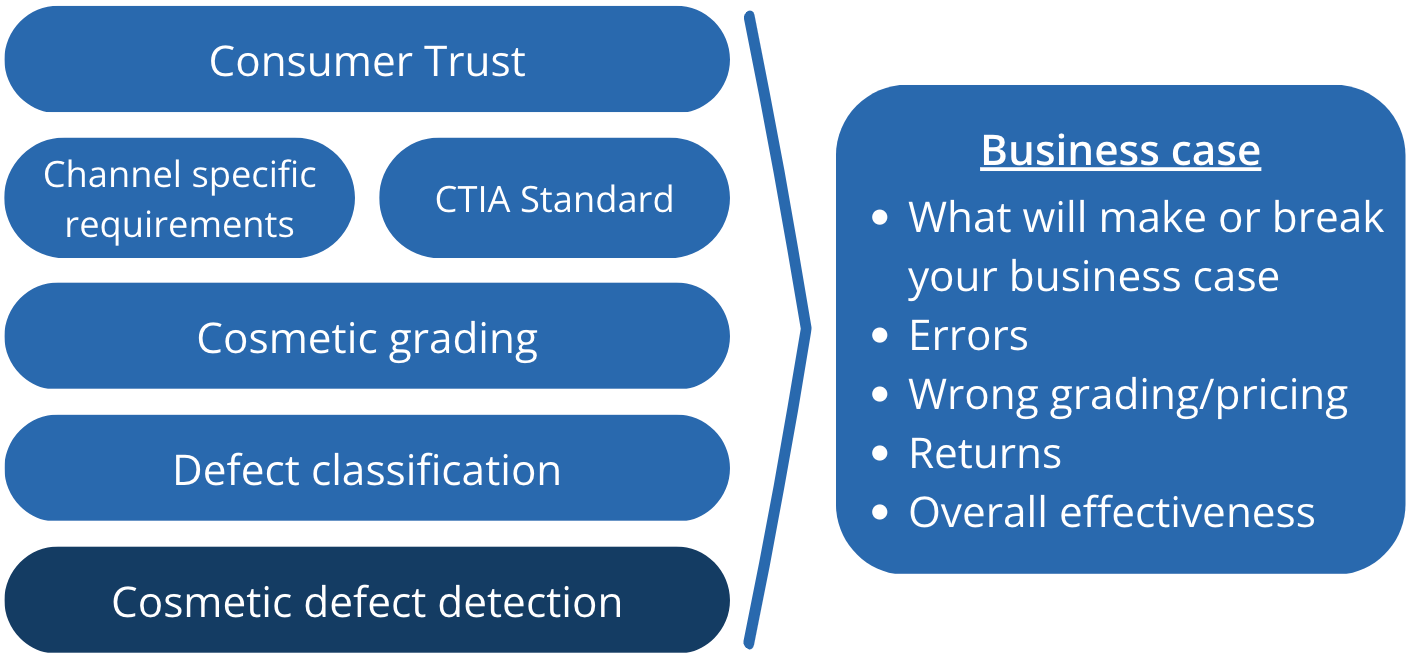

State-of-the-art cosmetic defect detection with AI is a key enabler for making profitable business in the refurbishment of smartphones. It is accurate, relentless, and objective and it beats humans in repeatability.

Your whole business case, pricing, consumer trust, everything is based on your capability to reliably analyze and classify the defects on the device.

How is your process today?

Humans are flexible and great learners. This is helpful in a business where you need to understand how visual problems might look on different types of surfaces. Grading the phones to different categories is based on experience, which can be trained. But even after a long experience, it is still very likely that grading errors happen. There are various reasons, like inattention, tiredness, or distraction. Another major issue is the constant change of personnel, which brings a variety into the grading process that should exist. This makes the work boring and highly error-prone.

How machine vision enhanced with AI can help

Machine vision can help to overcome human error in the visual inspection of smartphones by providing consistent and reliable inspection results. Unlike humans, machine vision systems can perform inspections at a high speed and with great accuracy, reducing the likelihood of human error.

Human inspectors may overlook or miss certain defects, particularly if they are not trained properly or are fatigued. Machine vision, on the other hand, can detect and analyze every aspect of the smartphone, ensuring that all defects are identified and addressed. By using AI to detect and identify defects, refurbishers can ensure that every smartphone is thoroughly inspected and meets specific quality standards, resulting in higher customer satisfaction and repeat business.

In addition, machine vision can be programmed to perform specific tests and measurements consistently, ensuring that the inspection process is objective and consistent. This can be particularly useful in identifying defects that may be difficult for human inspectors to see, such as hairline cracks or minute scratches.

Furthermore, machine vision can work 24/7 without needing breaks, allowing for increased productivity and efficiency. By automating the inspection process, manufacturers can significantly reduce the time and resources required for visual inspection.

One important gain is the data. Once you start using machine vision-based systems, you can start using data to improve your business case.

One example from real life: An end-customer tries to cheat the system by reporting that a phone he bought was graded as A, even though the actual grade was only C. He then tries to get his money back or to get a new phone from the seller. With a machine, that did the testing the seller could simply check the original grading and see that it is only a C. A customer that tries to cheat could easily be caught.

Most importantly the data will help you in the long run of your business. You can start to see if there are any anomalies in your process or how your suppliers for the phones differ from each other or performance over time.

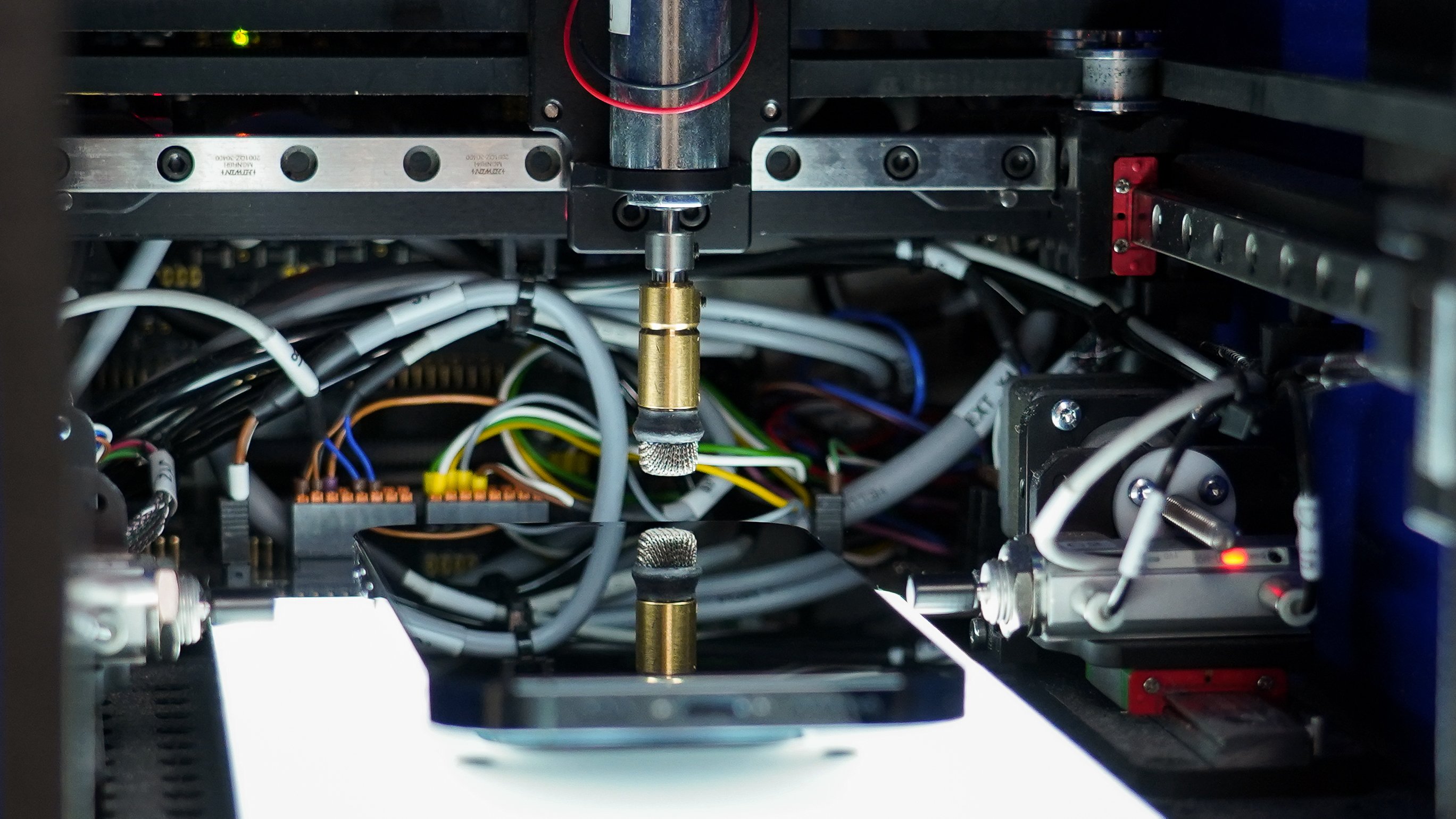

What OptoFidelity has to offer to cosmetic defect detection and grading process

OptoFidelity has a long experience and the best product on the market for the renewed smartphone business. Read more about OptoFidelity's FUSION and OptoFidelity's SCORE.

Working with OptoFidelity will help you to build the whole process for your business.

- Best imaging competence in the field

- Long and solid history with AI implementations starting from 2018

- Best products for the automating refurbishment processes

- Understanding of the industry's needs

We can offer products and competence, with unique knowledge backing it up.

If you are interested in reading how automation & robotics can help you with the functional testing of refurbished phones, please read our other articles related to this topic from Insights.

Learn more and join our webinar on 20th April

OptoFidelity is starting a series of webinars starting from April 2023, focusing on how state-of-the-art technology can help you improve your business case.

In our next webinar on 20th April, we will focus on AI-enhanced visual inspection. We will explain how it works and what you can expect. We will also dive deeper into how the near future will look.

Register here for our first webinar:

- Webinar US session, Thu, 20 Apr, 08:00 - 09:00 PDT / San Francisco

- Webinar ASIA + EMEA session, Thu, 20 Apr, 11:00 - 12:00 EEST / Helsinki

Speaker:

Kari Järvio, OptoFidelity, Head of Account Team- State of the art in cosmetic defect detection. The key enabler to customer trust in renewed smartphones business.

Juho Pastell, OptoFidelity, Software Engineer

- Examples of measurements and data sets

Mikko Lehtimäki, Softlandia, AI expert

- Future improvements we can expect from AI in visual inspection

Next webinars

We are planning to organize two more events in the near future. In our following webinars and events, it would be great to collaborate with you. We are calling as well you our partners to take part and present

Topics for next webinars 2023:

- role of standards and channel-specific criteria in grading

- consumer expectations and trust: what should we expect in the near future

- long and short-term benefits you can gain from automation & data for your business

If you have any an idea for a presentation or you would like to present some insights yourself, please contact us.

Do you want to stay updated about our future webinars, product releases, and industry updates? Fill out this form to stay always up-to-date about the newest developments in the industry.

Sign-up for our newsletter

Written by