AR/VR/MR Testing

Improve the quality of your waveguides and AR smart glasses with precise test systems.

Automating Metrology in AR Development and Production

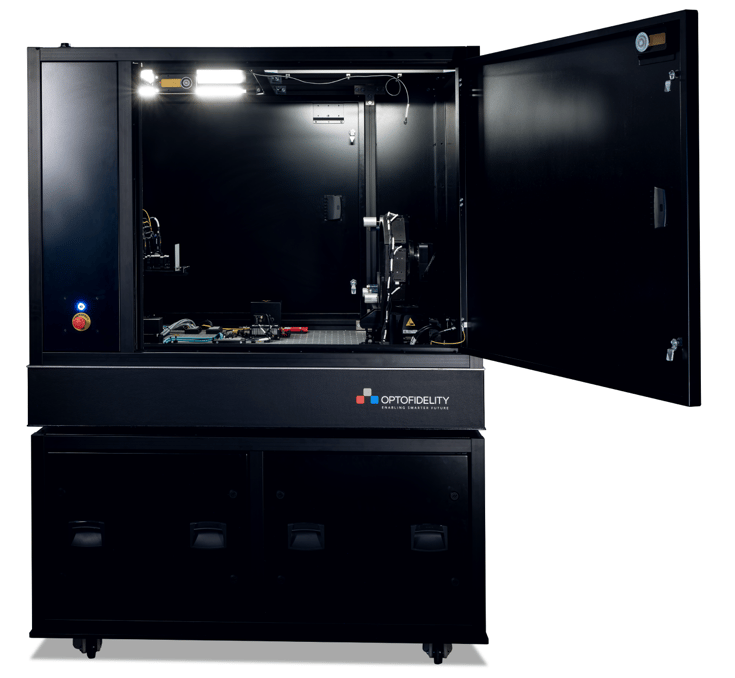

Off-the-shelf testing systems can streamline the R&D and production of waveguides and AR smart glasses. They can ensure consistency in quality control and lead to efficient and reliable manufacturing.

Our work at OptoFidelity is defining the standard for assessing the quality of waveguides and AR smart glasses, setting a new benchmark for AR image excellence. This isn’t just about technical achievements. It’s about paving the way for AR technologies to become a part of our everyday lives.

Find out how we do it.

Measuring Waveguide Image Quality

Waveguides play a crucial role in the functionality of AR smart glasses. The quality of the waveguides directly impacts the overall image quality seen by users.

Designing and manufacturing high-quality waveguides pose significant challenges. AR smart glasses must be lightweight and conform to strict form-factor limitations to appeal to a broad market, making it difficult to achieve the desired optical quality. Designers often experiment with different materials and structures in prototypes to simulate and measure image quality. Yet, many rely on manual and self-engineered measurement setups that slow down the iterative design process and often fail to provide detailed insights needed for improvement.

Assessing Waveguide Grating Quality

The main advantage of diffractive waveguides is also their greatest challenge. The miniature components in them, the gratings, must be measured at a picometer scale to assure high image quality. It is not enough to simply select the right material. The molding method, heat, and moisture impact the waveguides, requiring waveguide characterization throughout the manufacturing and assembly process.

Manufacturing waveguides require several phases, each with strict tolerances. Therefore, identifying production errors early is crucial, and high-precision tools are necessary to document and ensure that each phase of manufacturing meets the design specifications.

Challenges in Image Quality for VR Glasses

The quality of the VR glasses is the sum of the optics and the near-eye display used. VR glass imaging is similar to viewing the displayed image through a magnifying glass.

In standard flat displays, the single-pixel defects are less important. A mobile phone single pixel defect in the middle of a display won’t affect regular use. When viewing the same display through VR glasses, it will be magnified to exceed human eye resolution. Using the enclosed near-eye display system also increases sensitivity to brightness variation. A panel as a light source in VR glasses emphasizes all grayscale variations.

Challenges in Image Quality for AR Glasses

The biggest challenge for AR glasses is making a small form factor system with a large field of view and eye box. In addition to image generation challenges, everything should work smoothly with the real world.

Sunlight brightness is 1.6 billion nits. Mobile phone display brightness is between 500 and 1,000 nits. A large eye box generally means that the throughput efficiency will be low, which will set demands for the light source and waveguide. These are just some challenges related to ambient light in eyewear design.

Measuring Smart Glass Motion and Image Quality

Performance in AR/VR/MR glasses is crucial for creating a sense of immersion and presence. True presence is when users are fully engaged and enjoy their augmented or virtual reality experience. Achieving this becomes challenging with inherited significant setbacks on these devices, such as system latencies, drifting, and gitter. Even one failing aspect of presence can negatively impact the entire experience. Subpar performance can disrupt the experience, potentially causing motion sickness and nausea. Balancing technology and user perception, developers and manufacturers are tasked with synchronizing latency with motion tracking effectively while maintaining good image quality.

Testing and calibrating the temporal performance and image quality of AR/VR/MR glasses supports their development and quality assurance.

Ask Us About AR/VR Testing

Could we be a suitable partner for your business? Get in touch, and let’s explore how our products could help you.