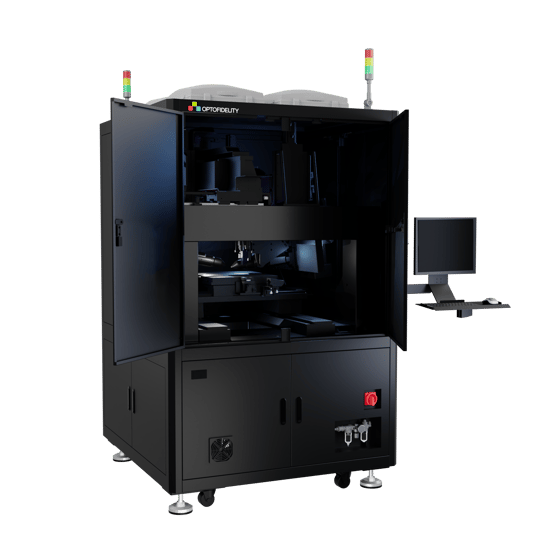

OptoFidelity Production IQ

Automated waveguide image quality measurement for AR waveguide manufacturing

FAST AND EASY IMAGE QUALITY TESTING

OptoFidelity Production IQ is a fast and easy-to-use image quality testing system designed for AR waveguide manufacturing environments. It is streamlined to meet predefined metrics and quality standards to ensure throughput and yield for volume manufacturing.

Consistent Quality Control

Production IQ prioritizes key quality control metrics defined by R&D and ensures they are consistently met throughout each phase of the waveguide manufacturing process. The tool is specifically engineered to perform fast measurements, significantly boosting productivity in high-volume manufacturing.

.png?width=544&name=automaticfeeding%20(5).png)

Cost-Effective Scalability

Production IQ is streamlined for scalability and cost efficiency and can be used for both manufacturing and pilot lines. It achieves cost savings with simplified motion control for stable, affordable operation. Integration with automated handlers can further reduce operational costs. Line capacity can be increased by cross-correlating multiple units and adjusting capacity with additional systems to maintain product consistency in full-scale production.

.png?width=544&name=automaticfeeding%20(6).png)