Solutions engineering

Precise measurement combined with precise automation

- 15 years in business

- 7500+ delivered test stations

- Standard product and custom deliveries to R&D and mass production

- Engineering services on three continents

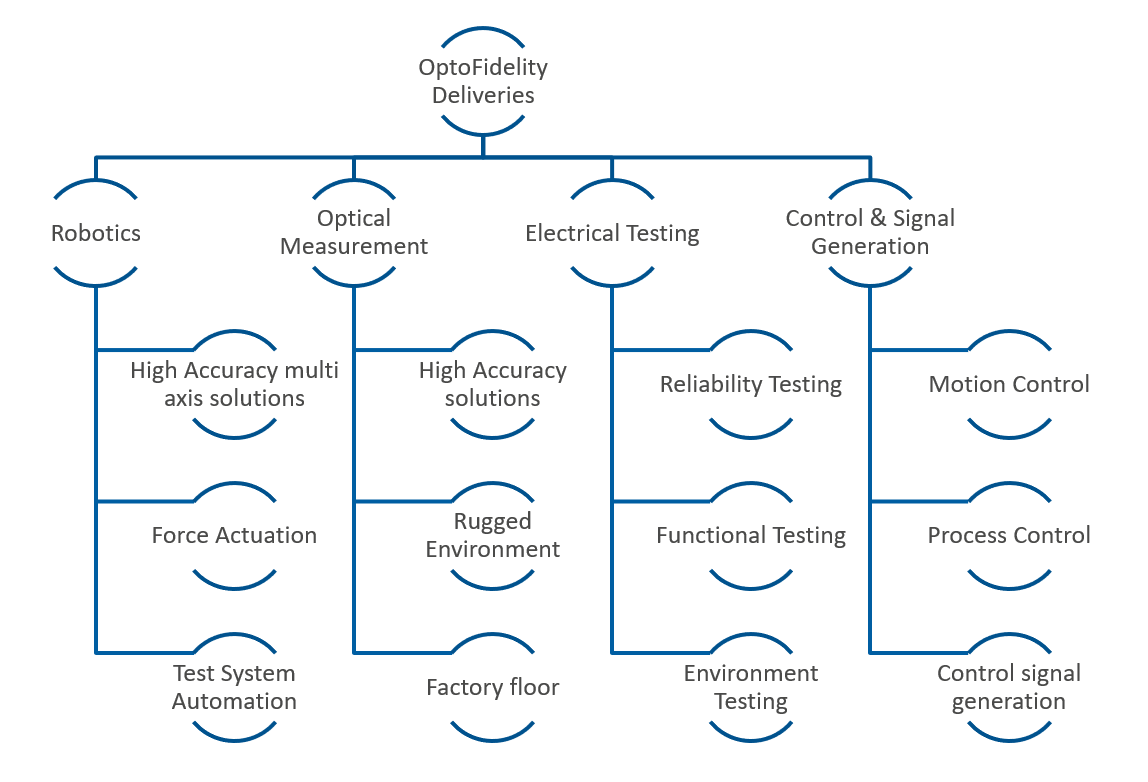

OptoFidelity's globally operating engineering teams are specialized to:

Optical metrology employs light to measure a myriad of quantities and phenomena, from surface roughness and display brightness to black hole mergers and polar ice coverage. Offering unparalleled precision, optical metrology sets the standards for other high-precision measurements, even for defining the unit of time. A vast amount of technology and applications are based on optics, and optical metrology is necessary to understand their performance.

Optical metrology is an integral part of all OptoFidelity solutions, either by directly providing the results or by facilitating further measurements. We use cameras, spectrometers, lasers and other light sources, and other custom and off-the-shelf optics paired with our state-of-the-art robots to characterize our customers’ products and systems. Among others, we have delivered solutions for R&D and quality assurance purposes for display and projection systems, mobile devices, AR/VR devices, optical waveguides, light sources and lasers as well as for surface quality inspection, mass production monitoring and medical devices.

To achieve the desired characterization capacity, our solutions exploit the many properties of light and various associated phenomena. In special cases, even effects such as Moiré and laser speckle – which are often unwanted – are utilized. Optical measurements are typically non-invasive, leaving the tested products in pristine condition.

Machine Vision, as a concept, has many interpretations. To some extent, it gives a machine (e.g., robot) an ability to see things: detect orientation, calculate the amount of objects, etc. Seeing things differs considerably from human vision: a machine vision system can also measure objects very accurately. Triangulation is a commonly used method, where the camera and the illumination form a geometric system for calculating distances.

Machine Vision systems are almost never static. A movement of some kind is typically present. By moving either the Machine Vision subsystem or the object to be inspected, the process and the inspection coverage can be enhanced. OptoFidelity is the grand master in combining high-precision robotics and Machine Vision. We know how to synchronize everything in order to get the best out of the measurement process.

The OptoFidelity team of experts builds off-the-shelf test systems including comprehensive measurement and analysis software kits. On top of that, the system can be custom-tailored starting from system add-ons all the way to fully customized measurement solutions, including user-defined data interfaces and output.

With every installation, we train our customers on-site to use our testers and build their test cases themselves or, depending on the customer, to do everything for themselves, from a fixed application user interface to system on-site maintenance.

Traditionally, testing is the final phase of the manufacturing process. This means that a failure to comply with the pass criteria will mean discarding the whole part or sub-assembly. In such an unfortunate case, all the steps and resources used during manufacturing would have been a total waste of time and money. The modern way of testing is to carry out multiple light inspections at earlier stages, in order to detect problems before they escalate.

Testing and measuring samples is a good start, but replacing visual inspection with automated test systems yields considerable advantage in terms of measurement accuracy, repeatability and speed. Recently, due to the emergence of smart devices along with added sensors and processing capability inside the devices, add-value tuning / calibration of the devices has been increased. As an example, the device display may be calibrated in order to harmonize all the production samples. As a sensor-related example, touch sensors might need per-product calibration in order to achieve the adequate user experience level.

OptoFidelity helps its customers at all stages of the product life cycle, from R&D concept development to testing during mass production. Our employees are there for you regardless of whether the task involves making a small tweak to existing system algorithms or working side by side with your R&D team to ensure the highest quality of your future product. Our service team is fully capable of building test cases and analysis for you as well as coordinating larger development projects together with OptoFidelity competence teams.

OptoFidelity’s professional teams provide both technical support and field services with the full technical capability and manpower to serve customers in all three continents: Europe, the Americas and Asia. In China, where the vast majority of current mass production takes place, OptoFidelity has so far supported projects in Chengdu, Chongqing, Kunshan, Nanjing, Shanghai, Shenzhen, Tianjin, Yantai, Zhengzhou and Zhuhai.

The project managers at OptoFidelity are experienced in collaborating with international customers on a wide variety of projects and can interact effectively despite time lag. OptoFidelity continuously invests in training its teams to develop themselves in global business management, project management and technologies.

Until today, OptoFidelity has delivered and maintained more than 8,000 test systems worldwide.

Precise measurement

Precise automation

Measurement and analysis

Agility and availability

OptoFidelity was born under the northern lights in the Finnish high technology community. Daring to dream big has been something that we’ve been doing all the way.

+358 44 430 0100

+358 44 430 0111

+358 44 430 0122

©2023 OptoFidelity. All rights reserved.